Industrial Support Applications

Transperancy and Quality Management you can show off

Warehouse condition monitoring is just one example that shows how protecting your or your customer’s investments in products or materials with our wireless temperature, humidity, and others logging and monitoring system can help to eliminate costly waste and product quality issues with a monitored and controlled warehouse and storage areas.

AIT’s scalable monitoring and control application provides a cost-effective warehouse and storage management solutions for all sizes of facilities.

Condition monitoring, for example is an efficient process, which saves considerable amounts of costs in secondary damage, and product damage. We also offer monitoring stockpile conditions.

- Warehouse Ambience

- Stockpile Conditions

- Air Quality and Compliance

- Fast ROI

- Transparent Customer Service

- Reduced costs

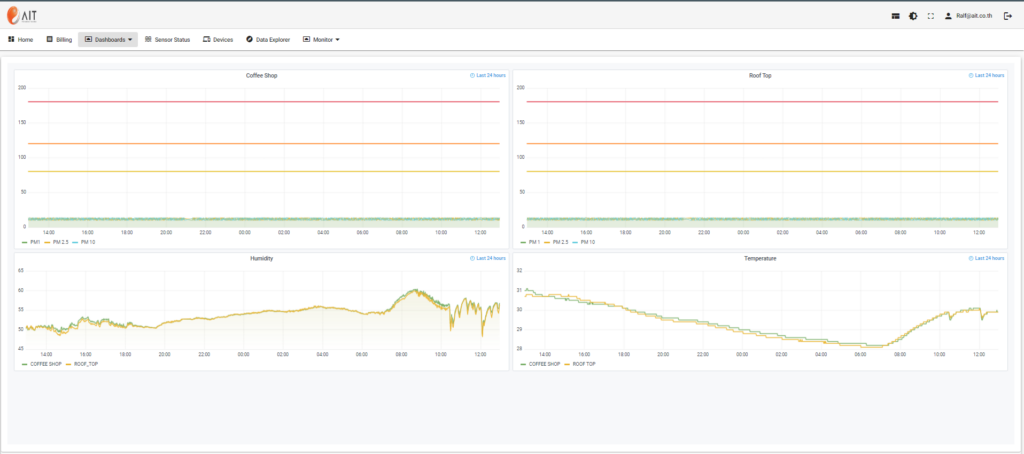

Ambient conditions (temperature, humidity, PM1, Outdoor PM2.5, and PM10) as part of Condition Management Compliance

Warehouse Ambience and Stockpile

In addition to the warehouse condition monitoring, we offer a rather unique feature, the tracking of the temperature inside the product, which is especially important for products that need to keep temperature in a certain range to assure optimal quality or to avoid spontaneous combustion as it may be the case in certain products such as animal food, oilseed-based products, coal, charcoal or certain fertilizers. Like with the ambient monitoring the customer can free define the thresholds for sending notifications or generating an exception report

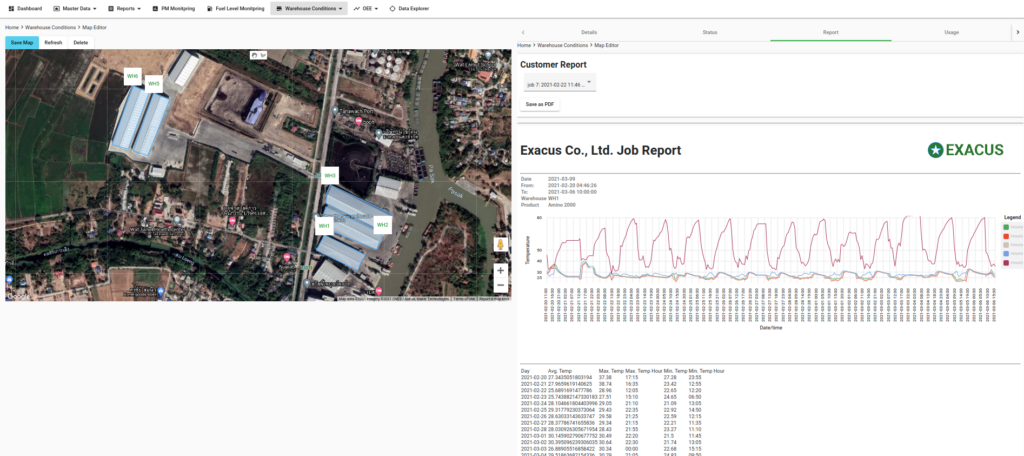

Customer Job Management and Reports

The Stockpile sensors (SPT) are typically wireless sensors, which can be moved between jobs, depending on particular service level agreements. The sensors are communicating via 3G or LORAWAN with the server and are mapped to a warehouse and job by the operations employees. The other attributed are configured using the job editor

Job reports provide a summary of a complete job with summarized data or a ad-hoc snapshot of a running job.

These reports can be viewed by customers at any time and can saved as PDF and are often send to end customers.

We use many of the applications we are offering ourselves or have some installed in a showcase environment. We would be glad to welcome you today at our offices to take a good look or talk to us about your requirements